MBA finds its roots in 1971 when, at the age of 17, Martino Bresciani began his business of adjusting and finishing mechanical parts. In 1985, Martino founded a mechanical workshop of which his son Alessandro became a partner in 2008 once he graduated in Mechanical Engineering. In 2013 Martino sold his shares to Alessandro Marmentini, who has been in the mechanical sector for years, who contributes with his experience to the evolution of the current MBA.

More than thirty years characterized by commitment and attention to detail, always looking for continuous innovation and new challenges. It is thanks to this spirit that MBA has grown from a small artisan workshop to a precision mechanical workshop.

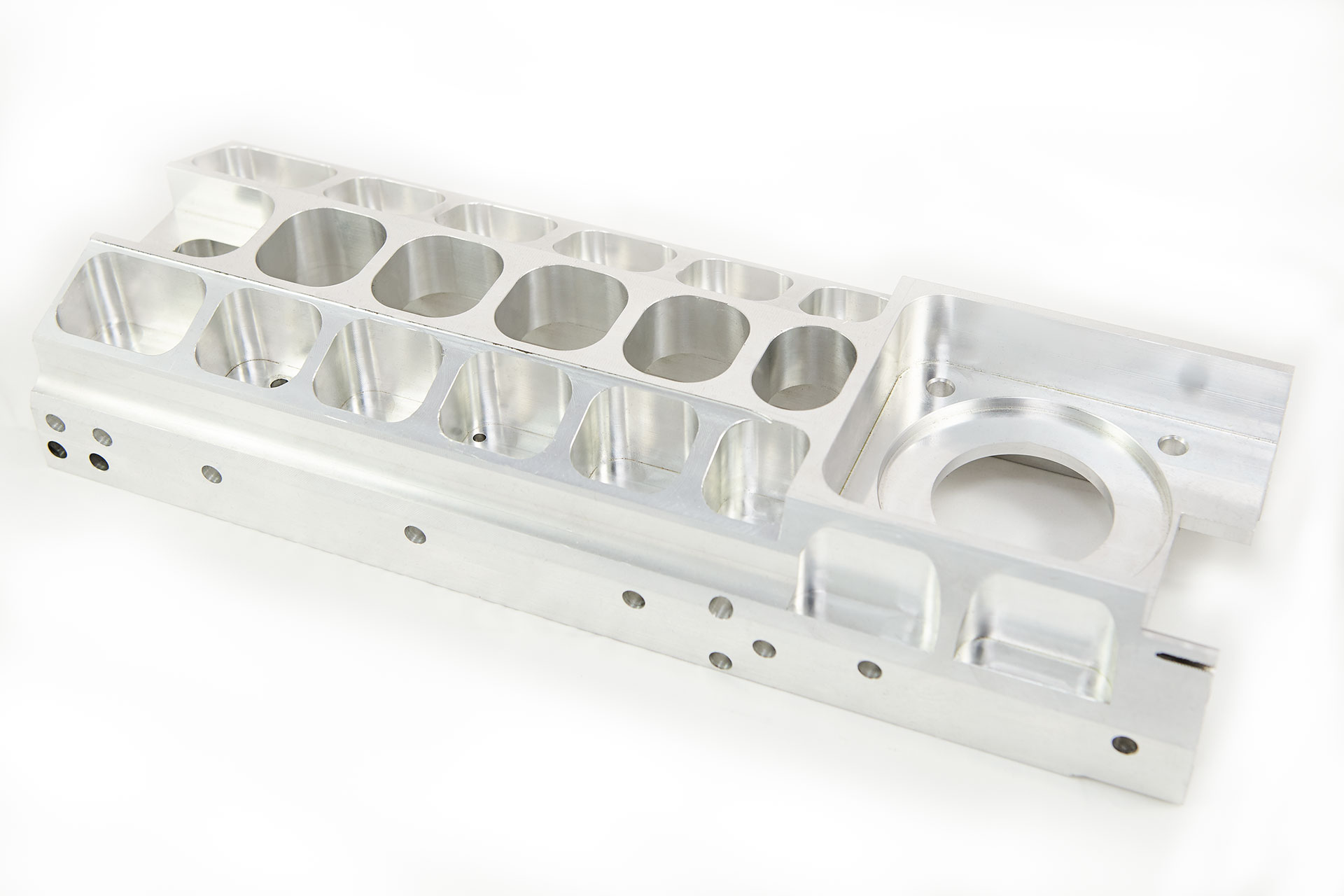

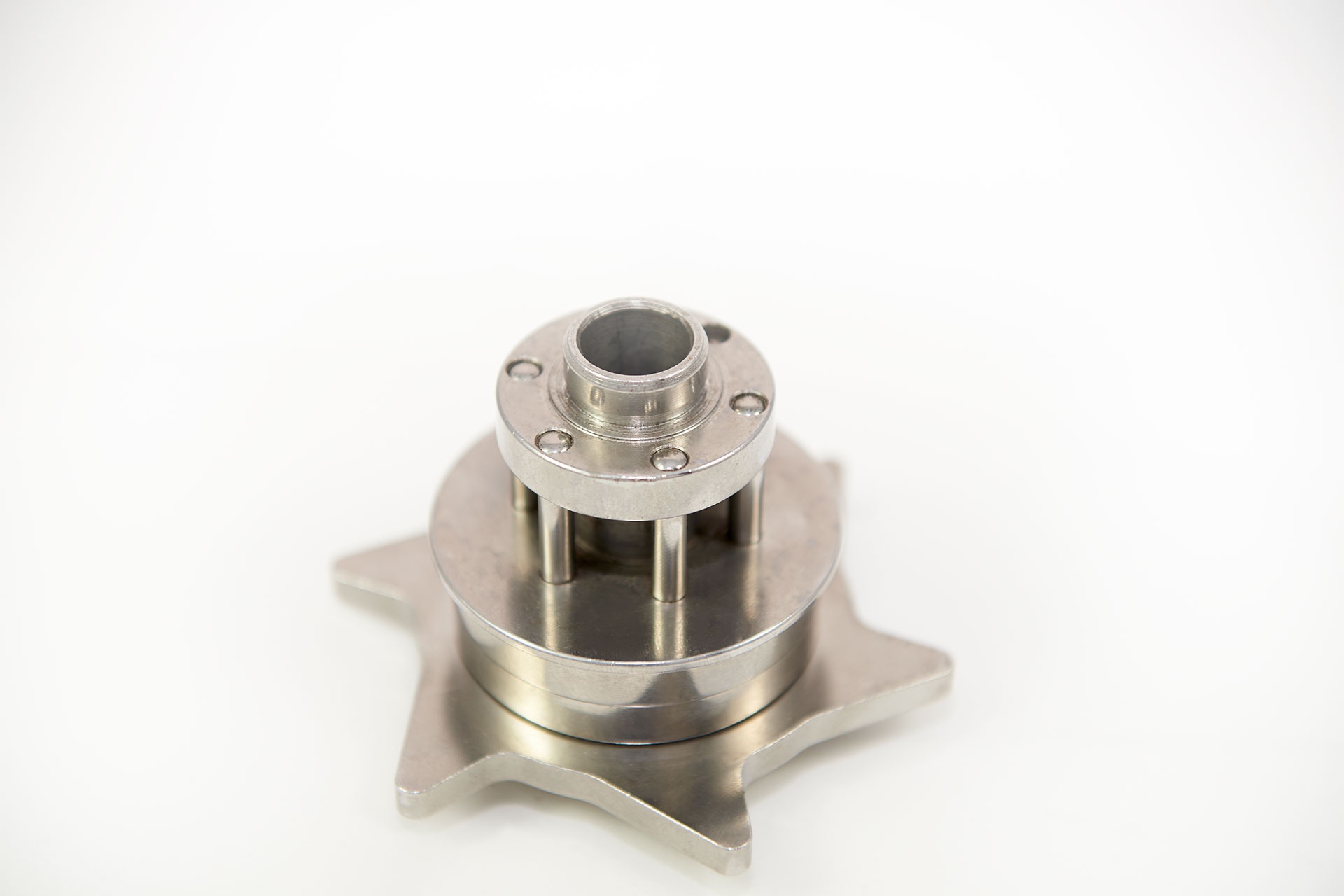

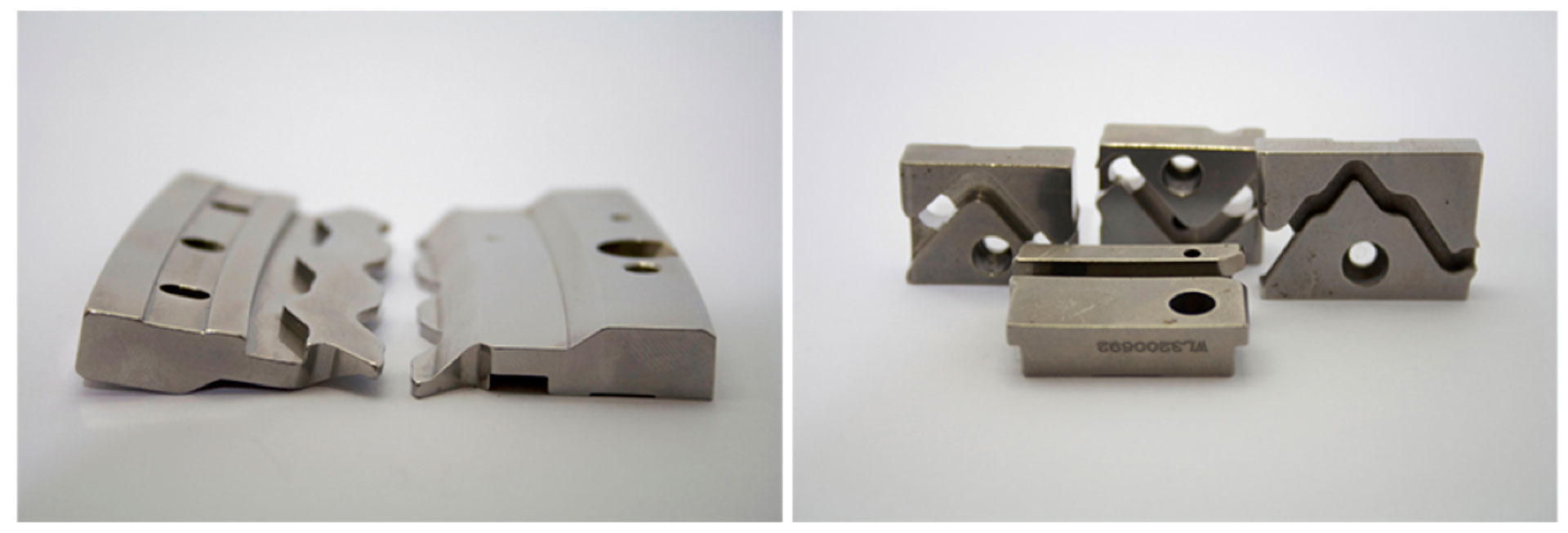

We manufacture components mainly intended for the textile machinery, arms manufacturing, biomedical sectors, and we produce parts for 3D scanners and automation.

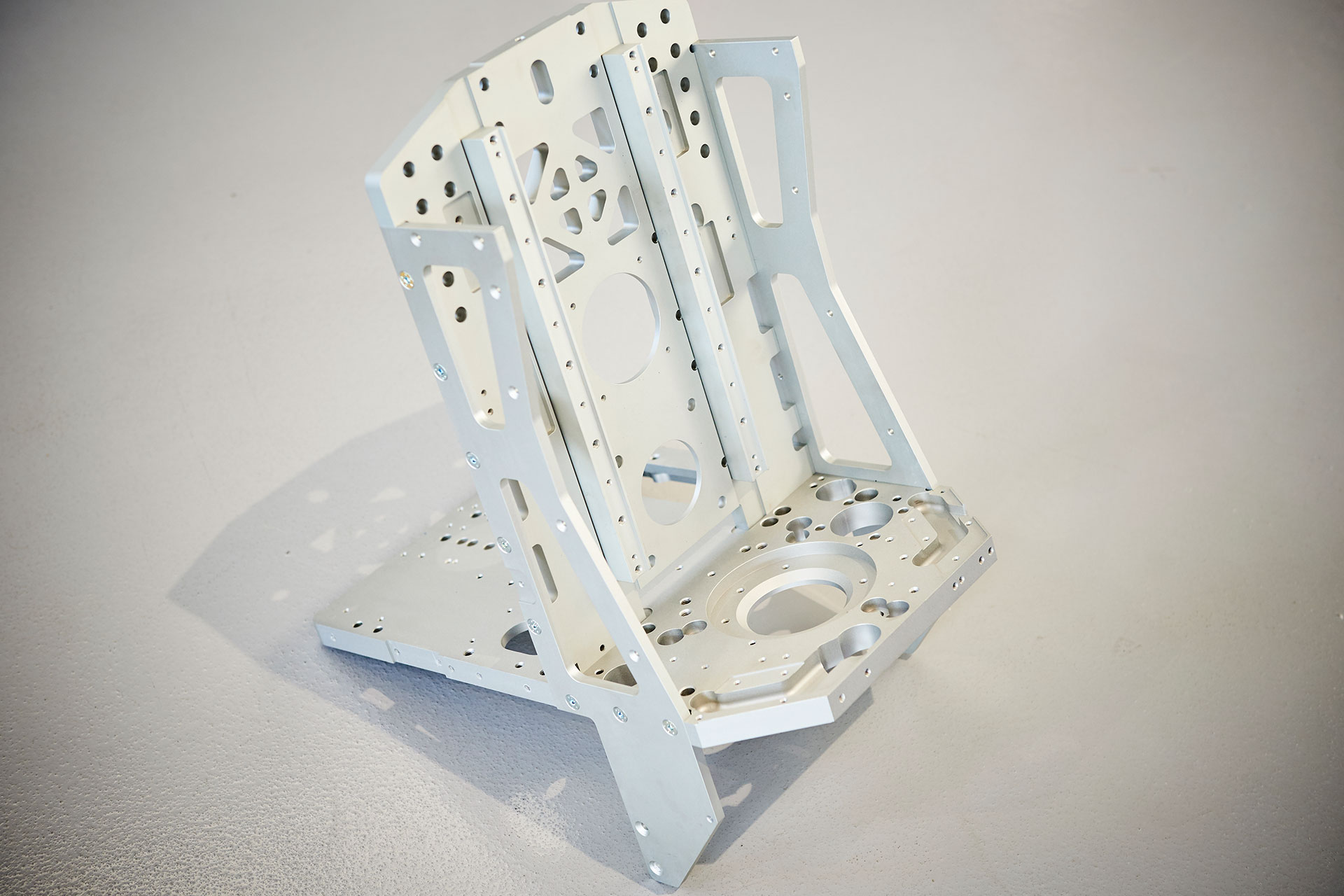

We work steels and alloys starting from bar or moldings with maximum working strokes of 600x600x400mm.

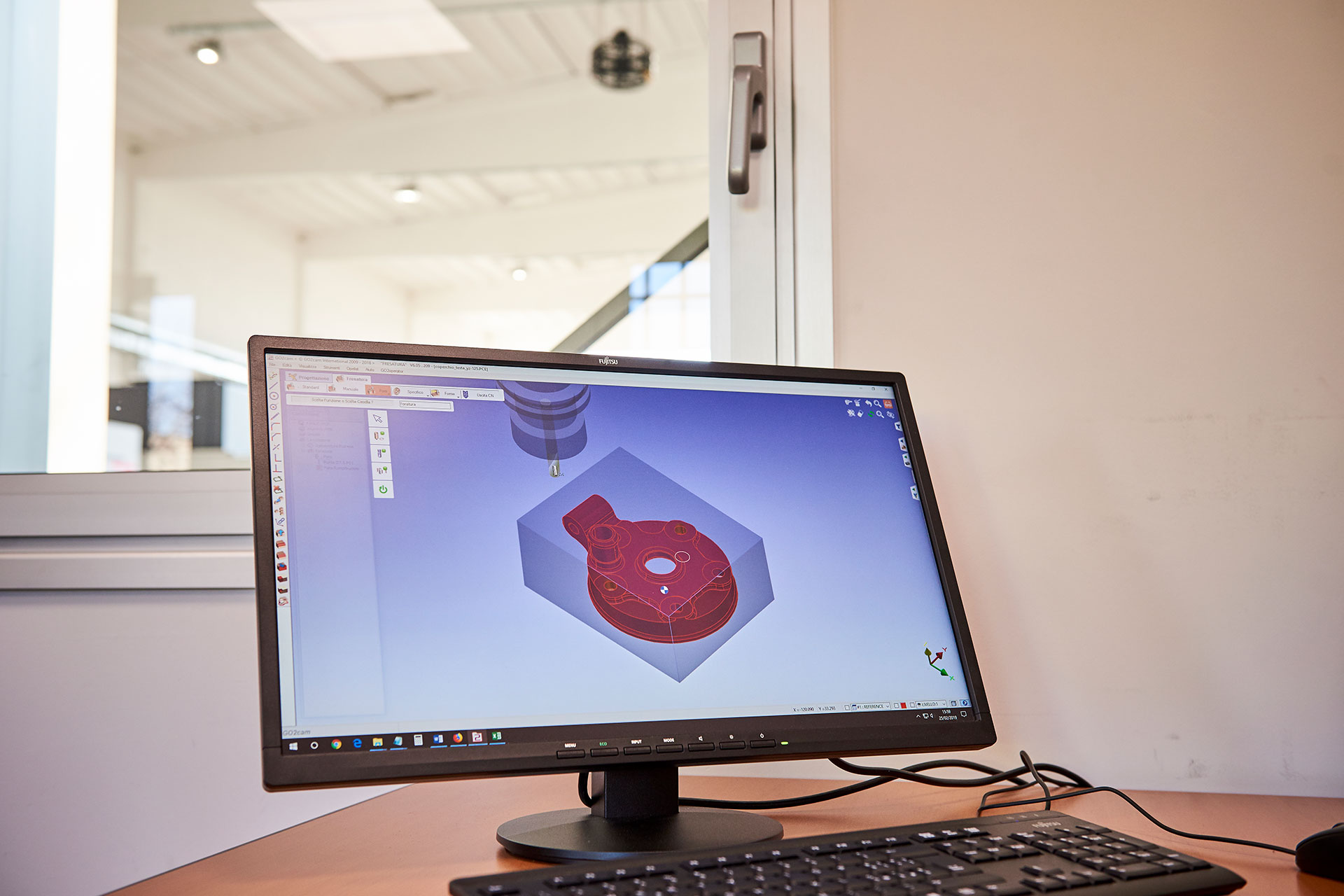

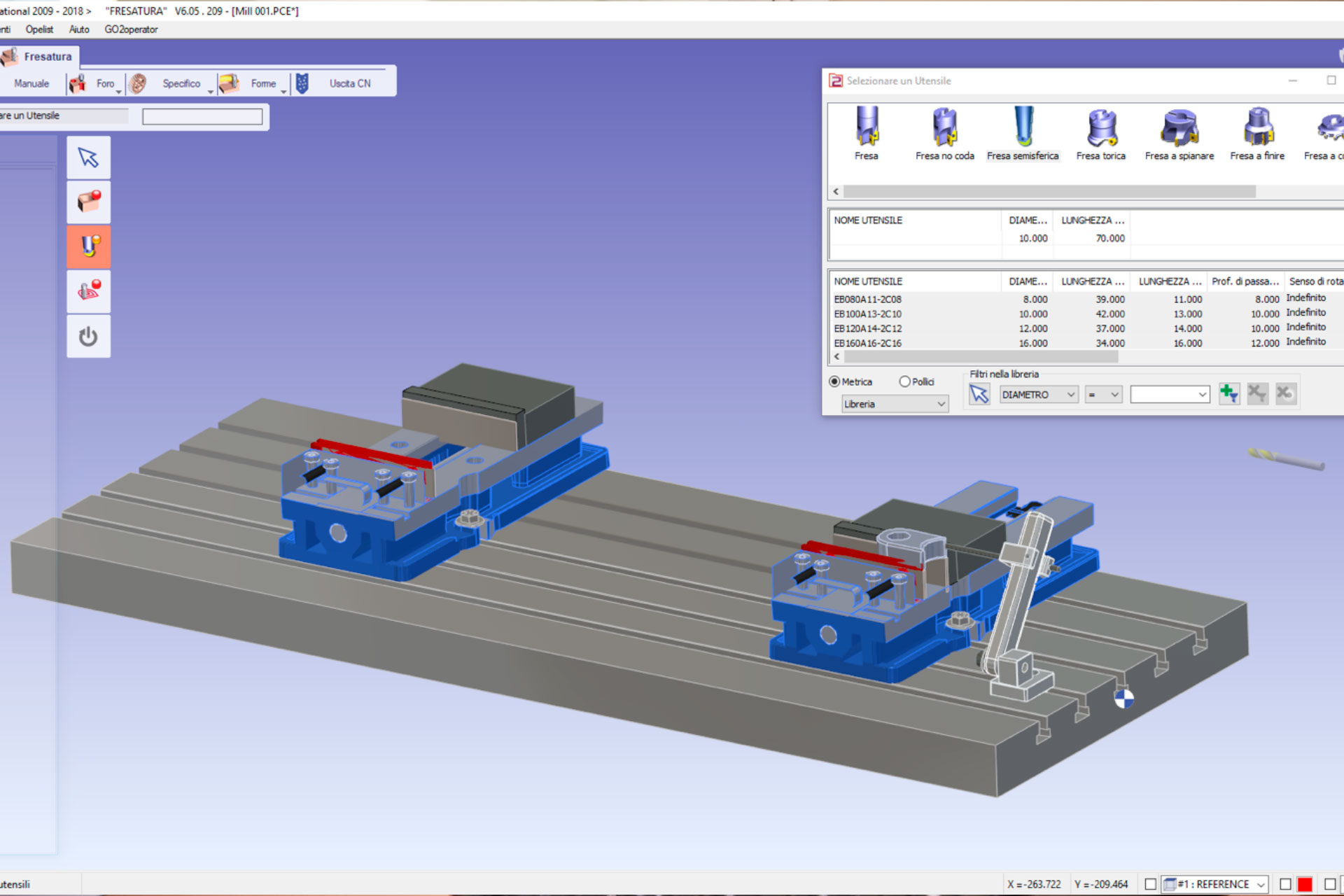

The use of CAD CAM programs supports operators in the construction of components, allowing us to create complex geometries.

Using external collaborations, we supply finished components subjected to surface treatments such as nickel plating, chrome plating, zinc plating, burnishing, phosphating, DLC ceramic coatings or anodizing.

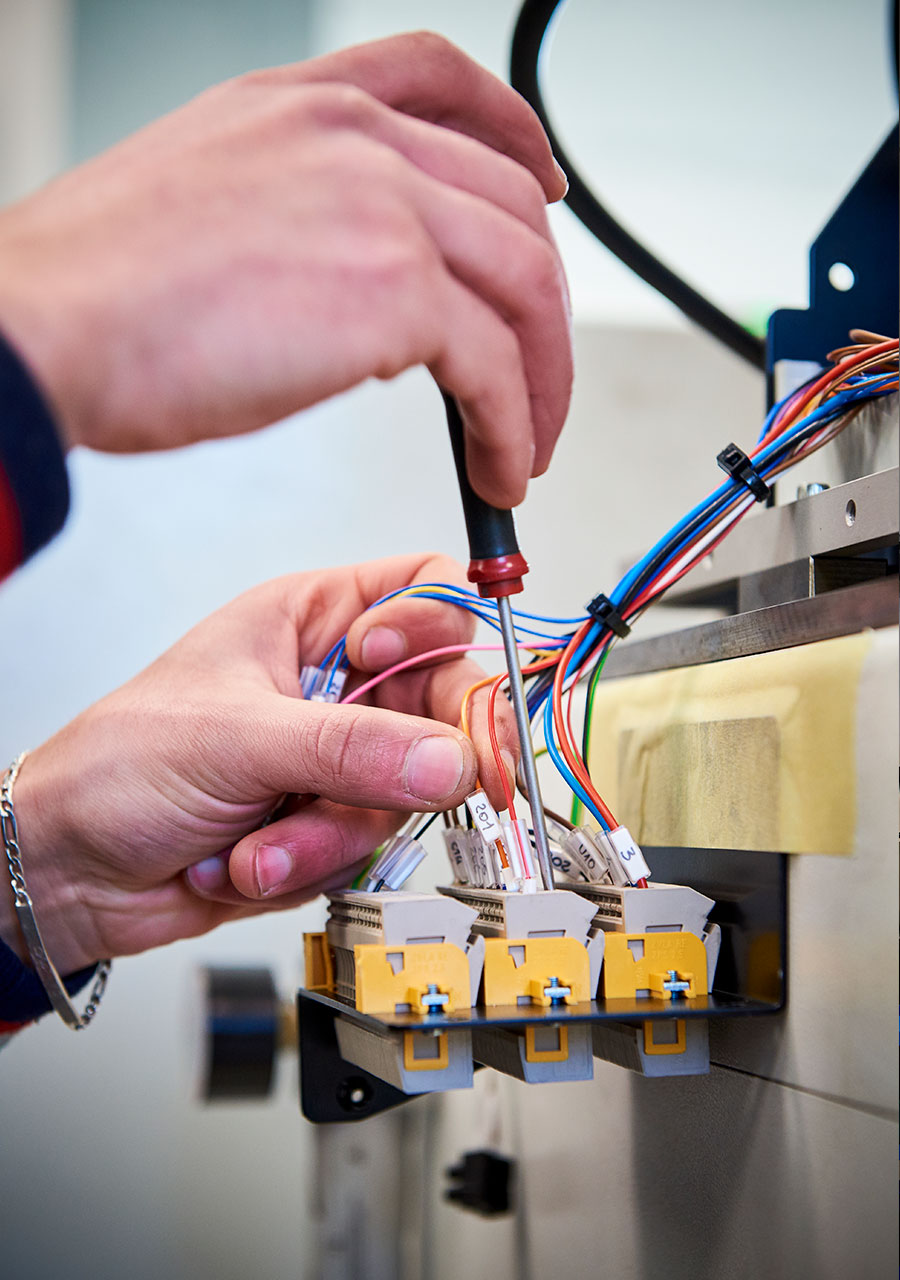

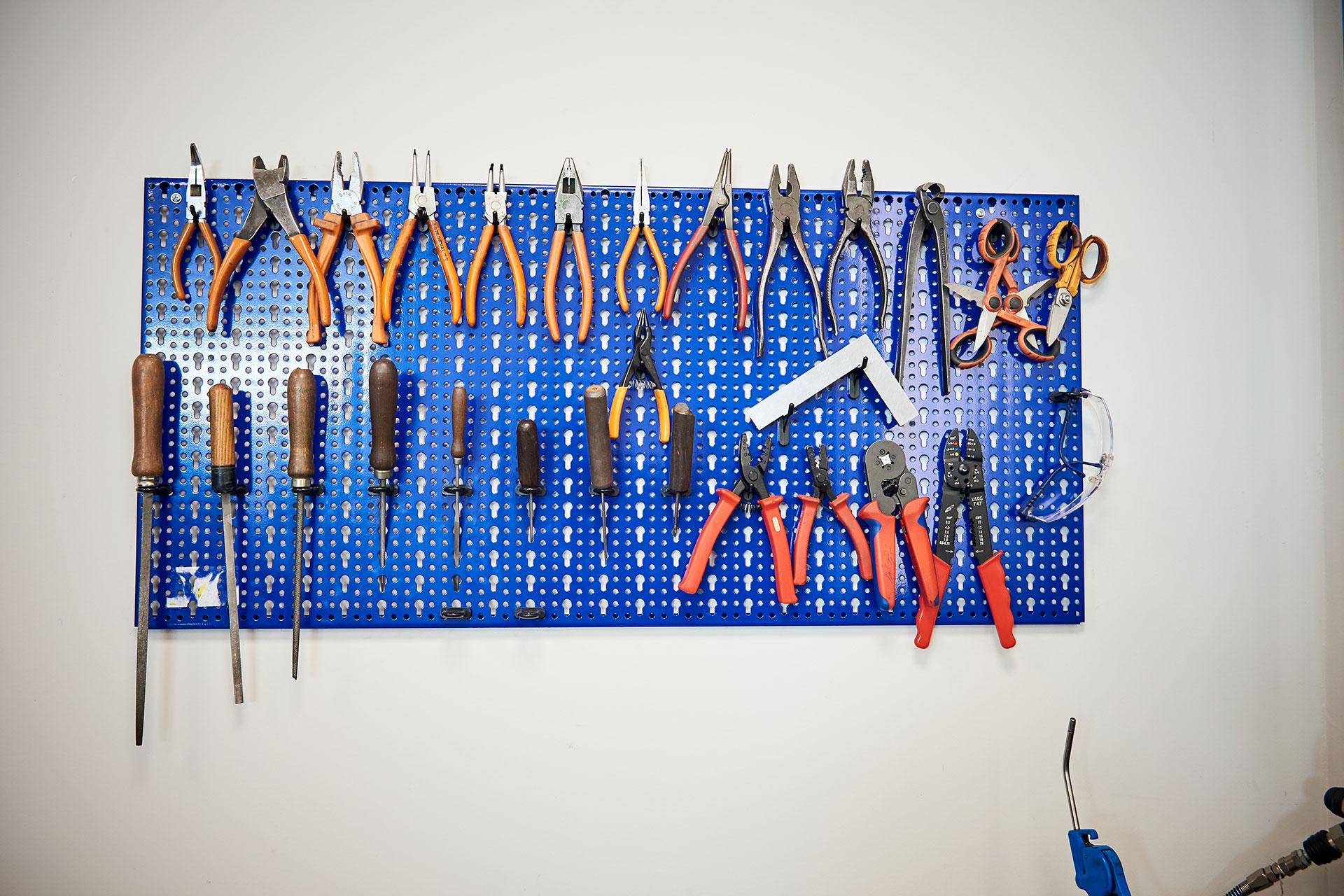

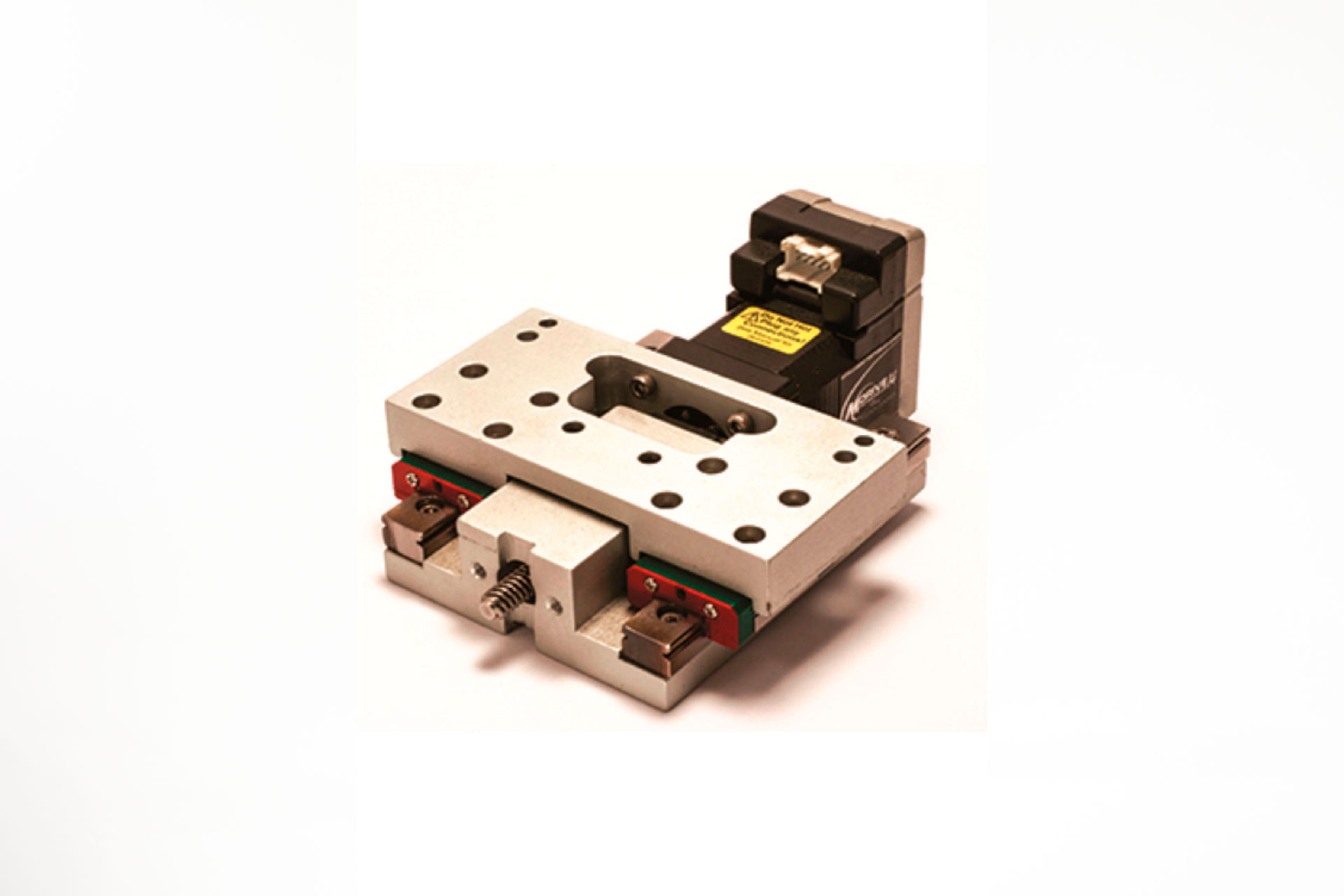

In 2011 we created an ASSEMBLY DEPARTMENT to provide the customer with the assembly service of small groups or of the entire machine, both from a mechanical and electrical point of view. In case of request, the machine is delivered complete with the relative test phase.

The presence of the AUTOMATIC WAREHOUSE allows us to have an excellent internal organization and at the same time a simple and traceable storage of both single components and pre-assembled components.

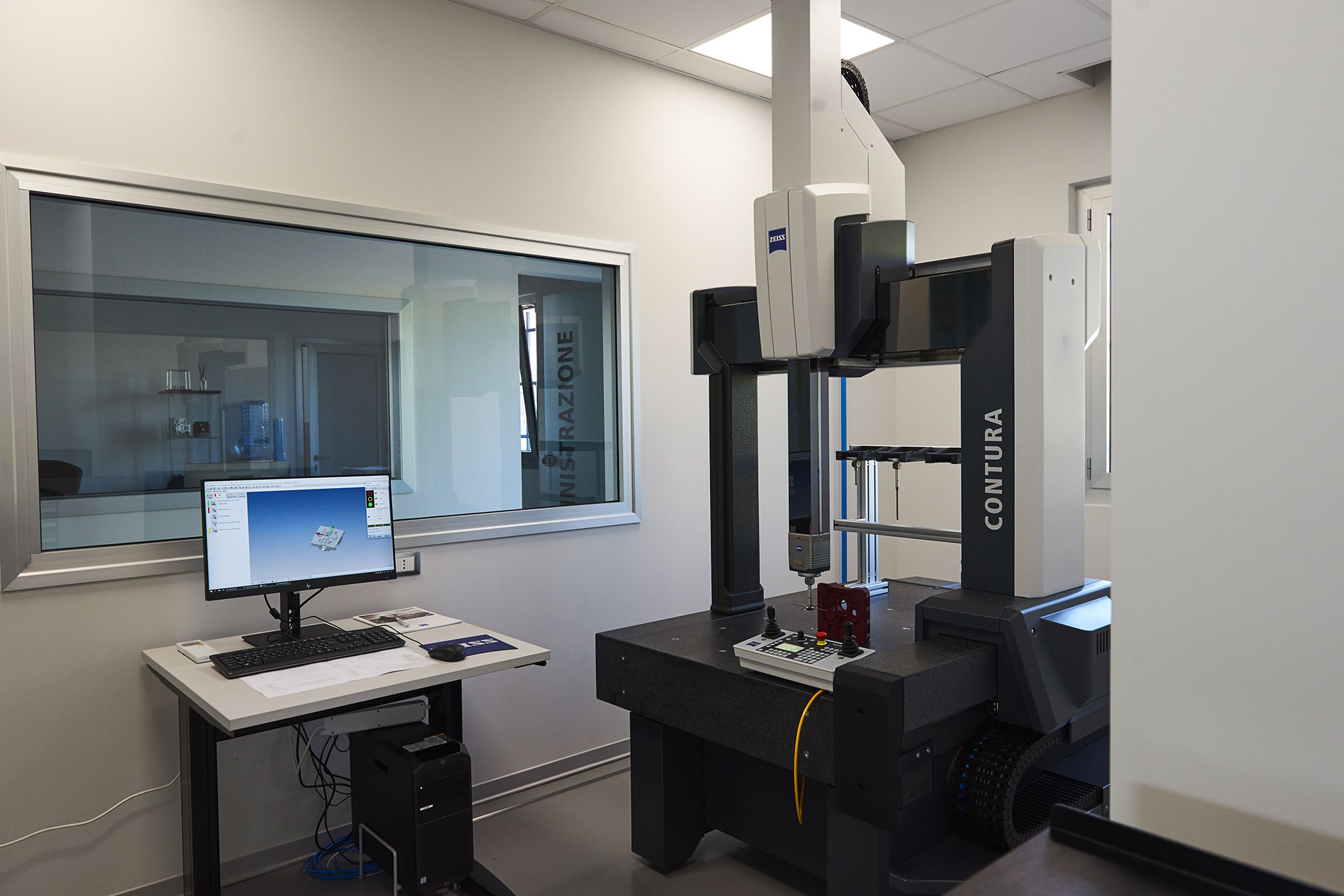

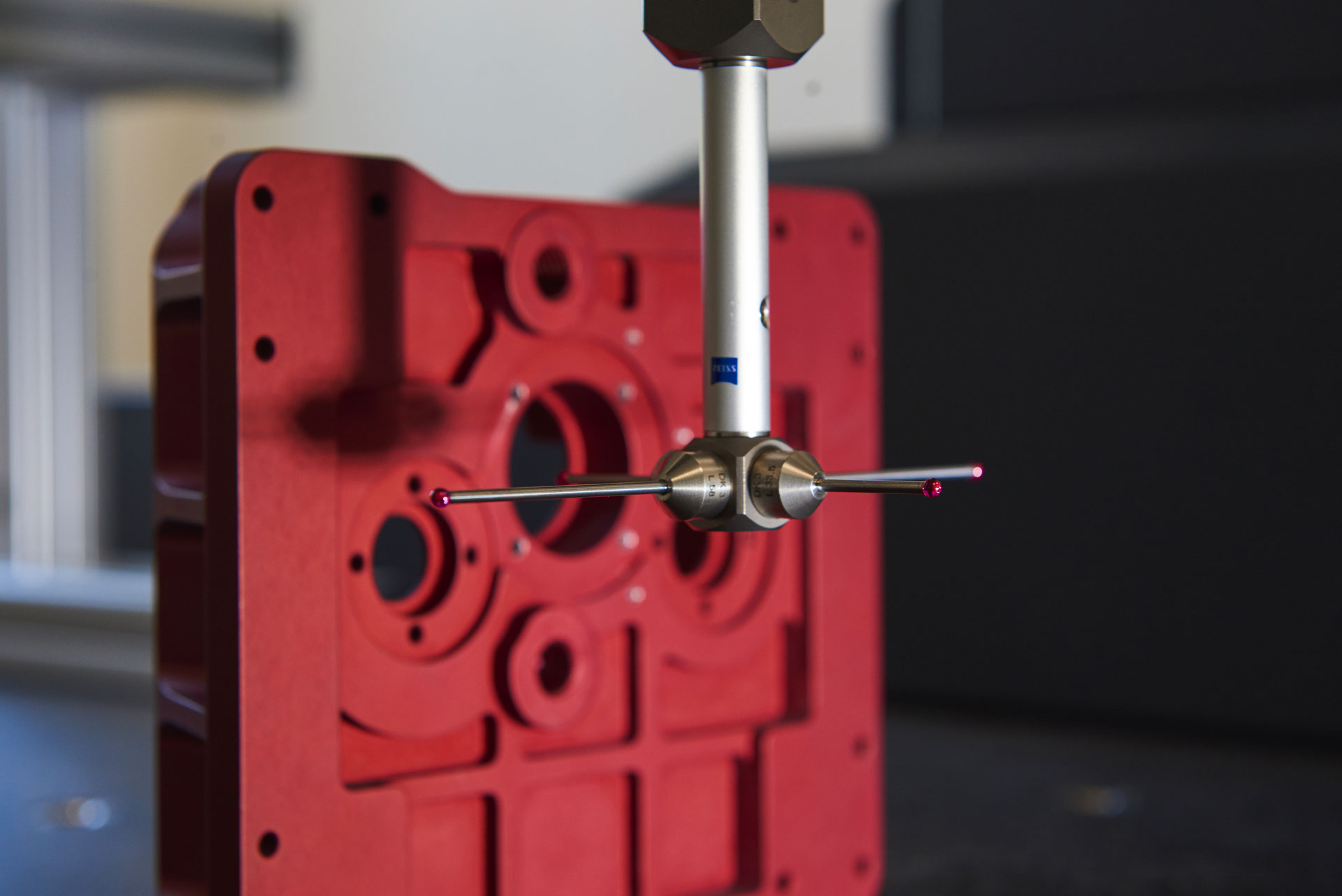

The quality of our products is guaranteed by an initial check by the operator during the processing phase (using calipers, buffers, centesimal dial gauges for exteriors and interiors, MITUTOYO LINEAR altimeter, GALILEO durometer, MITUTOYO PH-3500 profile projector, roughness tester) and a second check using the ZEISS CONTURA CMM which certifies its correctness.

For any need, contact us by filling out the form below or by calling the number indicated.

Call us

+39 030 358 0529

Send us an email

info(at)officinamba.it

Where we are

Via Artigianato, 12

25030 Torbole Casaglia (BS)